What is PrintedLabs?

Anyone who has ever planned, built and ultimately played with a "project" using building blocks or other construction toys will know the great feeling of having created and applied something from scratch. It is no different with free experimentation and research in all STEM areas. Generally speaking

- after a basic idea, the complex overall construct is first broken down logically into individual subsystems,

- individual requirements are defined for each subsystem, the concept is analysed and tested,

- The concept is analysed and tested, the necessary problem solutions are developed and finally implemented without impairing the overall function,

- independently develops the necessary specialised knowledge or researches it if necessary,

- many other important competences such as: Handling numbers, data, mathematical concepts in a creative, motivating environment.

PrintedLabs is intended to be a platform for exactly this free, motivating and creative experimentation, with a continuously growing number of project ideas, inexpensive self-build lab equipment from the 3D printer and, if necessary, suitable software. We are aimed at:

- Teachers who want to present a demonstration experiment, explain how an instrument works, or have their students/pupils carry out simple experiments themselves.

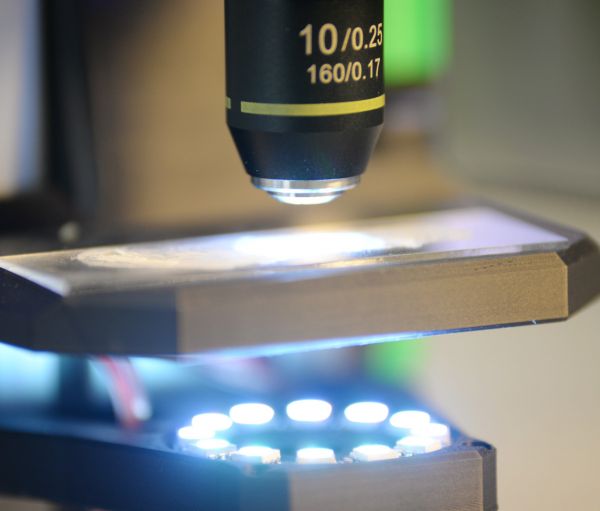

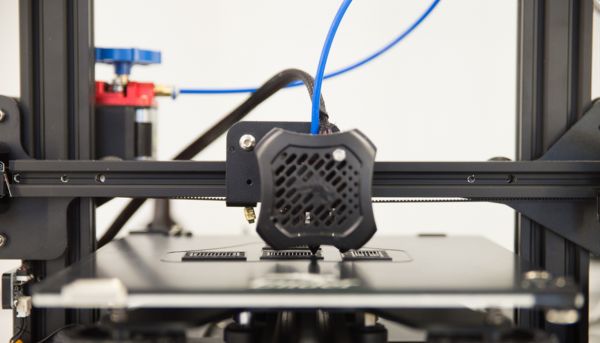

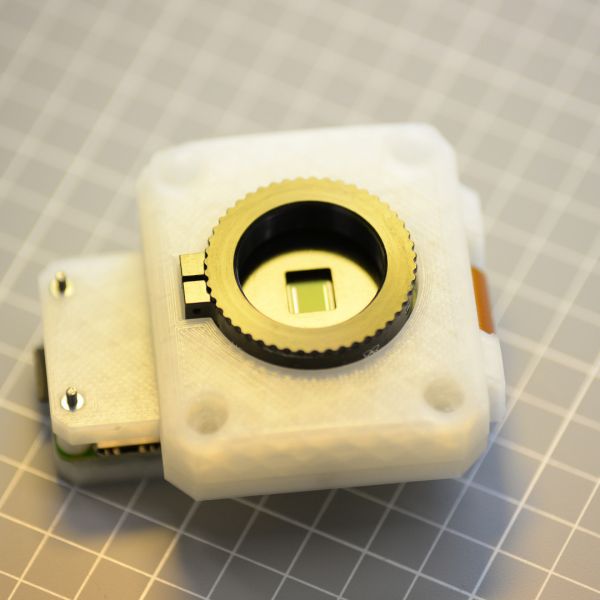

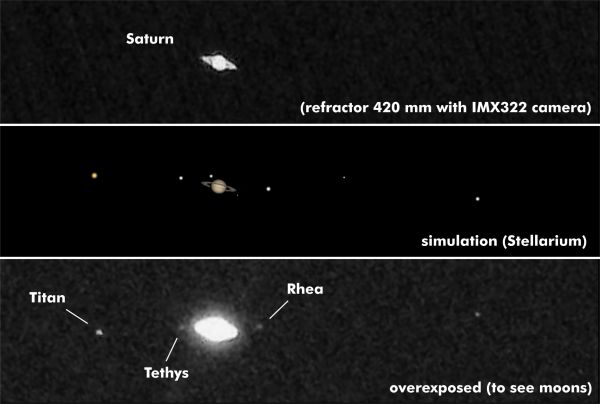

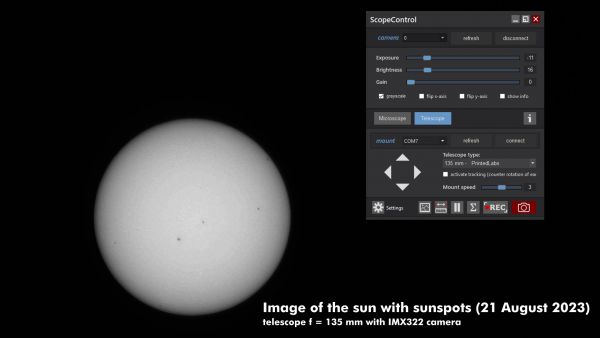

- Pupils** who enjoy tinkering and researching and want to make their own small telescope or microscope to gain their first experience of the cosmos/microcosm.

- Anyone** who is curious, enjoys experimenting, physics and other STEM subjects and is looking for simple but good laboratory equipment to realise their "projects".

Since 2021, the developed components have also been used in the basic practical course for physics teaching at the University of Bayreuth.

To take action yourself ...

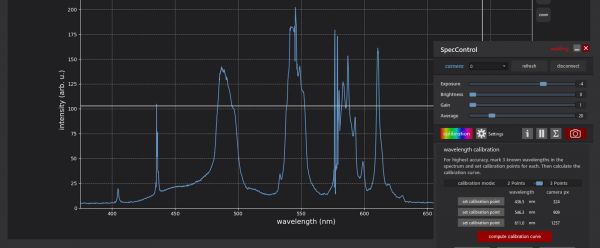

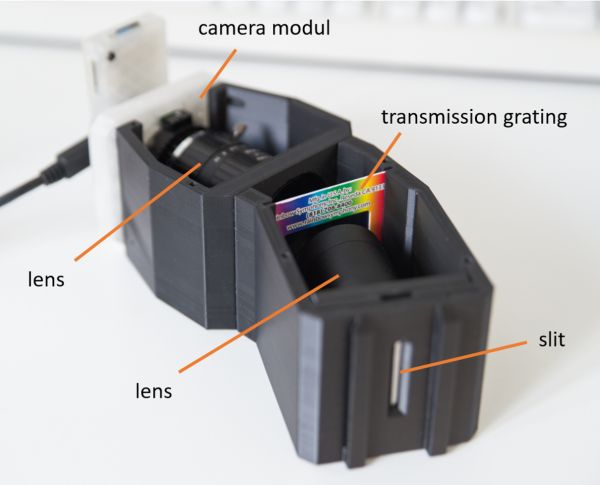

... and to reproduce or modify an experiment presented by us or to design your own, all components developed by us can be reproduced and used by yourself. For this purpose, we offer free of charge our developed [3D print models](../../model database/) and the corresponding software for download, as well as the corresponding instructions and tutorial videos. The production of the equipment requires nothing more than a standard 3D printer (price approx. €200), glue, various standard screws/small parts and, in some cases, simple soldering work. In addition to the actual experimentation, the focus is always on a cost-effective, simple and enjoyable construction of the instruments/parts, which contributes to understanding how they work. The demand we place on ourselves is:

- To make science and STEM subjects fun through self-built "lab equipment" and its application.

- Developing analytical and creative thinking, problem-solving skills and learning structured working methods for setting up and carrying out scientific experiments.

- The teaching of basic knowledge of data processing and the evaluation and interpretation of measurement data.

- Good performance for detailed experimental results.

- Compatibility of all components and any associated software.

- Simple and cost-effective assembly with standard tools and additional components.

- Robust 3D models in printing, manufacturing and handling.

- High modularity to enable "free experimentation".